Presetting – the key to success

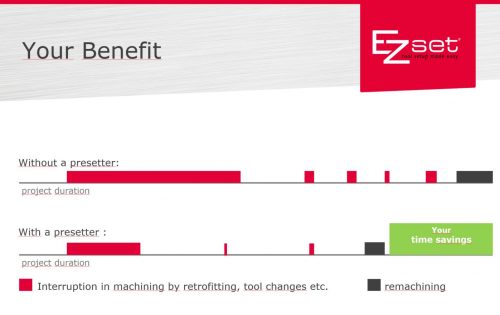

EZset tool presetters enable you to save time and money, putting you one very decisive step ahead of the competition. Your tools are set and measured while your machine is producing chips – without any downtime.

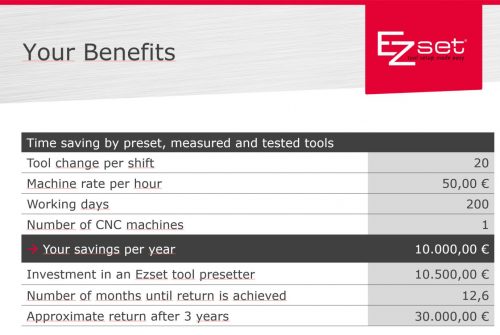

The right kind of tool preparation pays rich dividends

Precisely measured tools, optimized machine uptimes and longer tool service lives make sound financial sense. Your productivity will be boosted by at least 15%. EZset tool presetters pay for themselves in no time. They are easy to use, low-budget but high-performance.

Simple!

- The EZset concept: The user comes first and foremost, and is able to work efficiently on a day by day basis.

- The very latest image processing turns tool presetting into child’s play

- Fast training thanks to the intuitive EZset operating concept

Precise!

- Image processing system with dynamic crosshairs for inductive and precise tool measurement, independent of the operator

- Brand quality such as Bosch pneumatics, THK guides and Heidenhain glass scales deliver precision and a long and maintenance-free service life

- Tool holder spindle SK 50 with ultra-precise repeatability and integrated calibration edges

Economical!

- Three in one: Tools are measured, set and tested

- All-in-one turnkey solution in a package that includes the table, adapter and utensils storage tray and label printer

- Quality ‘Made in Germany’ at an unbeatable price/performance ratio

- Worldwide service

DOWNLOAD BROCHURES

EZset_Flyer_EZgoICbasic_1_9_18en